Your cart is currently empty!

FINISHXPERT FILLER – THE 3D PRINTING COATING

FinishXpert Filler is an advanced filling spray, carefully crafted to enhance the quality of 3D printed objects. Tailored for a wide range of 3d printing technology, this cutting-edge formula ensures exceptional results on various printing materials.

400ml Packaging.

600 in stock

Description

FinishXpert Filler is an advanced filling spray, carefully crafted to enhance the quality of 3D printed objects. Tailored for a wide range of thermoplastics used in FFF and FGF technologies such as PLA, ABS, PET, PETG, PP, and PA, this cutting-edge formula ensures exceptional results on various printing materials.

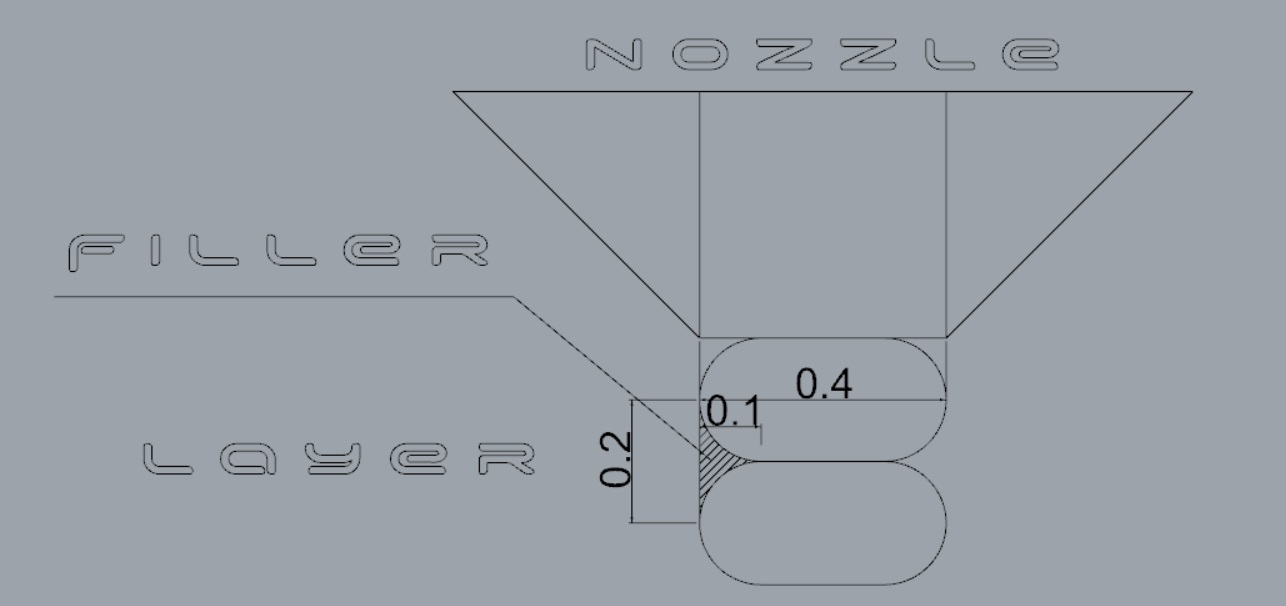

This filler provides a filling power of approximately 15-30 microns per pass. Available in an elegant RAL 7042 grey color, it is easily sandable, making it ideal for smoothing 3D printed objects with 0.2mm layers and a 0.4mm nozzle by applying 2 or 3 layer of coat. Apply a coat, sanding, and then applying another coat with further sanding, if needed repeat one more cycle and a smooth surface is achieved.

This product is effectively usable even on parts made of PA12 using SLS technology and on parts made with SLA using photopolymerizing resins. In both cases, it contributes to obtaining a smooth, rigid, and easily sandable surface, reducing surface roughness, correcting imperfections, or serving as a base for subsequent painting.

Moreover, FinishXpert Filler serves multiple purposes beyond filling. It can be layered atop other putties like FinishXpert grey bodywork putty for additional finishing layers. Additionally, it acts as an excellent base coat for subsequent painting, providing a strong grip for paint adhesion.

Usage instructions are straightforward: begin with a thoroughly cleaned surface, shake the can well before use, and spray from a distance of 20-25cm. Allow it to dry for 2 hours before sanding or painting. For optimal results, apply thin coats at intervals and sand with either P800/P1000 wet sandpaper or P600 dry sandpaper.

FinishXpert Filler is proudly made in Italy.

In essence, FinishXpert Filler is the go-to solution for achieving professional-grade finishing on 3D printed objects, providing a smooth surface ready for painting and ensuring exceptional results with ease.

Here are some fascinating examples of FinishXpert Filler application on 3D prints made with various materials and technologies:

1. Treatment of a PLA model:

Gorilla Low Poly statue, printed using FFF technology with black PLA using a 0.4mm nozzle and 0.2mm layers. After printing, the statue was treated with 3 layers of FinishXpert Filler, interspersed with sanding, to achieve a smooth surface.

Finally, two coats of matte black acrylic spray paint were applied for a flawless finish.

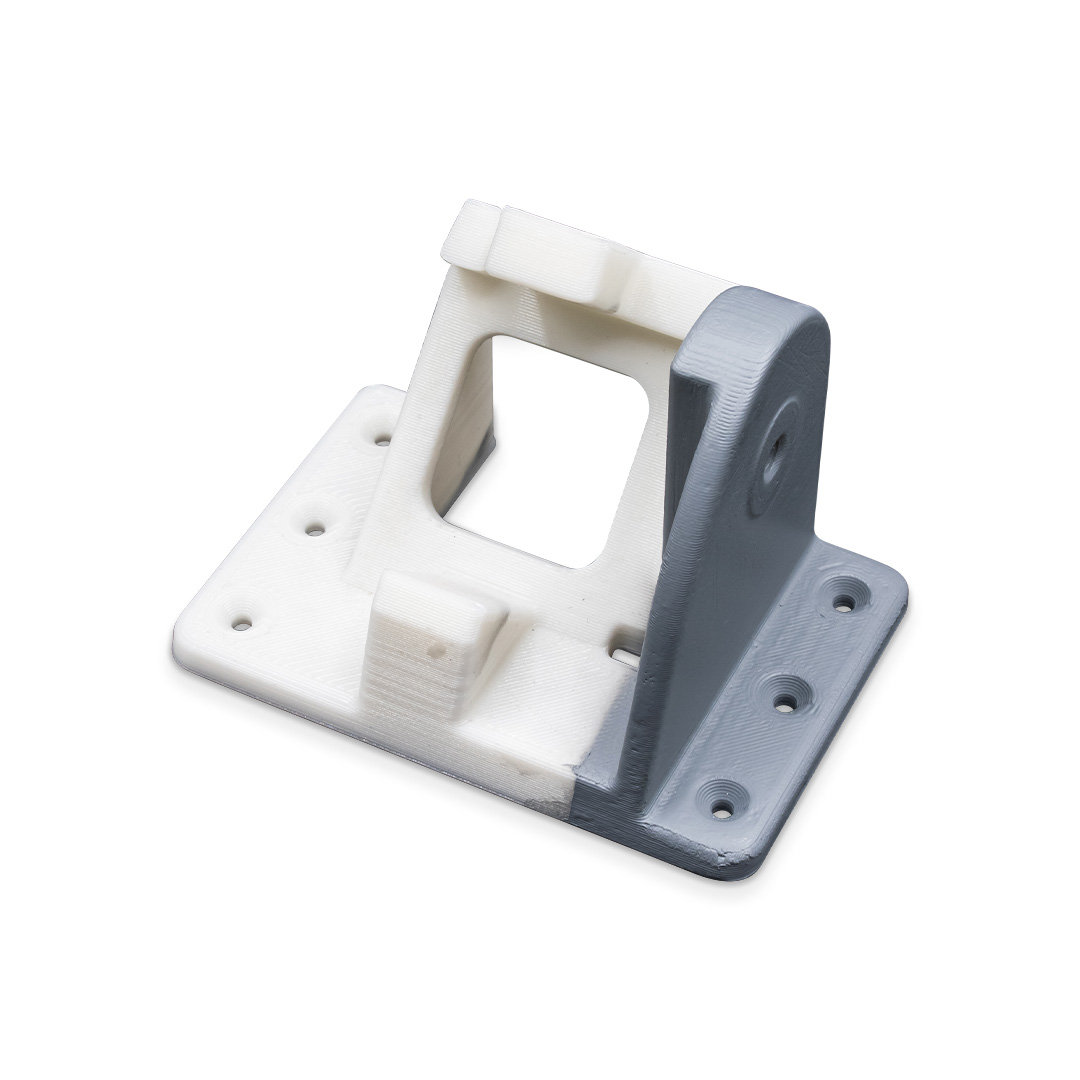

2. Finishing of a cosplay armor in PLA:

The various components of the armor, printed in FFF with PLA and a 0.2mm nozzle and 0.4mm layers, were treated with 2 layers of FinishXpert Filler, interspersed with sanding,

and then painted with chrome-effect acrylic spray paint.

3. Final treatment with FinishXpert Putty:

We refined a reproduction of Michelangelo’s David head, printed using FGF technology with PLA as the base material, a 1.5mm nozzle, and 1mm layers. The head was first treated with FinishXpert Stucco and sanded with P80 sandpaper, then a layer of FinishXpert Filler was applied, sanded with P220, followed by a second layer of Finishxpert Filler as a surface finish.

Here are some outstanding results achieved across a wide range of materials:

FFF PLA;

FFF PetG Carbon filled;

FFF ABS;

FFF Pet;

FFF Nylon Carbon filled;

FFF Polypropylene (PP);

FFF Nylon Glass filled;

FFF Thermoplastic Polyurethane (TPU) Shore 95A (NOT COMPATIBLE), after fully drying on TPU parts, Finishxpert Filler does not retain the same flexibility as TPU and tends to crack when TPU parts are bent;

SLS PA2200 through Selective Laser Sintering;

Reviews

There are no reviews yet.